Copyright © 2023 Shanghai Shengyun Rotational Moulding Co.Ltd

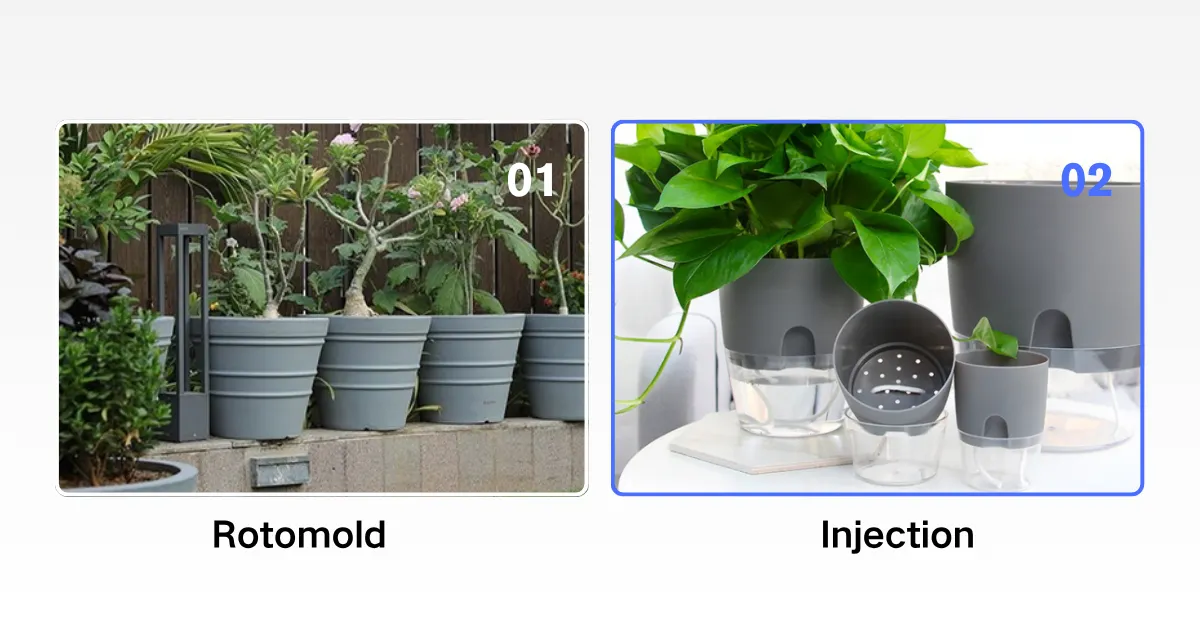

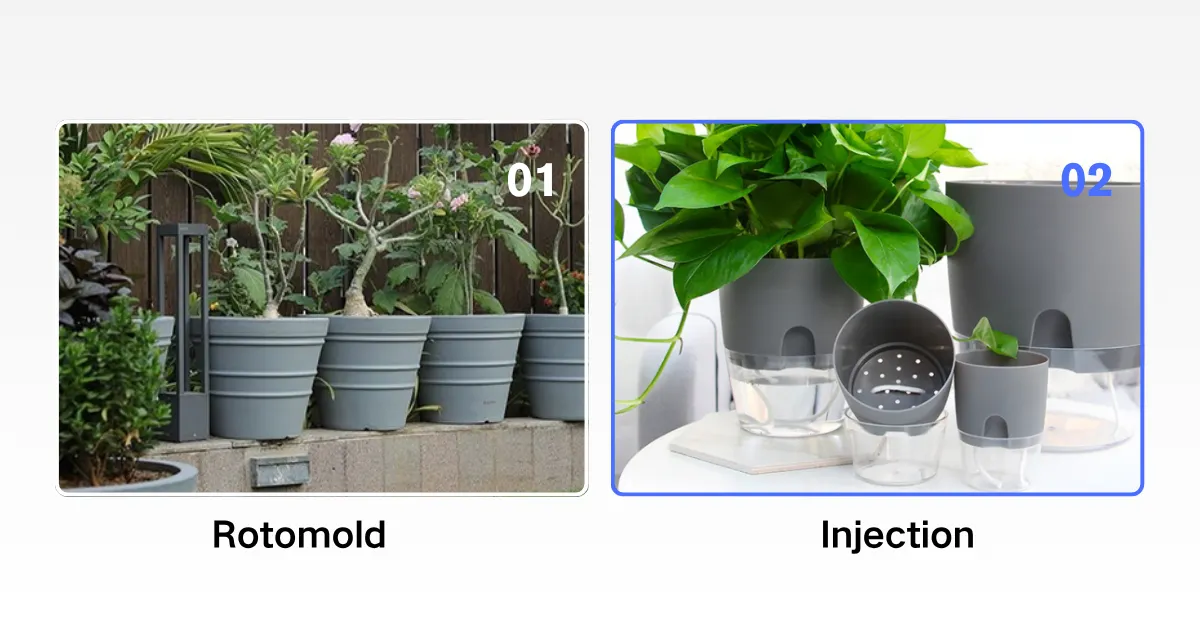

Rotomolded Planters vs. Injection Molded Planters

2025-07-30

Keywords: Rotomolded planters, injection molded planters, best outdoor planters, durable garden pots, custom planters.

When choosing planters for gardening or home decor, the manufacturing process significantly impacts durability, aesthetics, and functionality. Rotational molding (rotomolding) and injection molding are two common plastic manufacturing techniques. So how can we make the decision between rotomold Flower Pot and the inject one? We can choose from some factors below.

1. Superior Strength & Durability

Rotomolded Planters:

a) Seamless, One-Piece Construction – No weak points or weld lines, making them highly resistant to cracks and impacts.

b) UV & Weather Resistant – Can be formulated with UV stabilizers for long-term outdoor use without fading or brittleness.

Injection Molded Planters:

a) Visible Mold Lines – Prone to stress cracks along seams over time.

b) Less Weatherproof – Often requires additional coatings for UV protection.

So if you need flower pot to decorate your beautiful outdoor garden or yard, the rotomold one will be better.

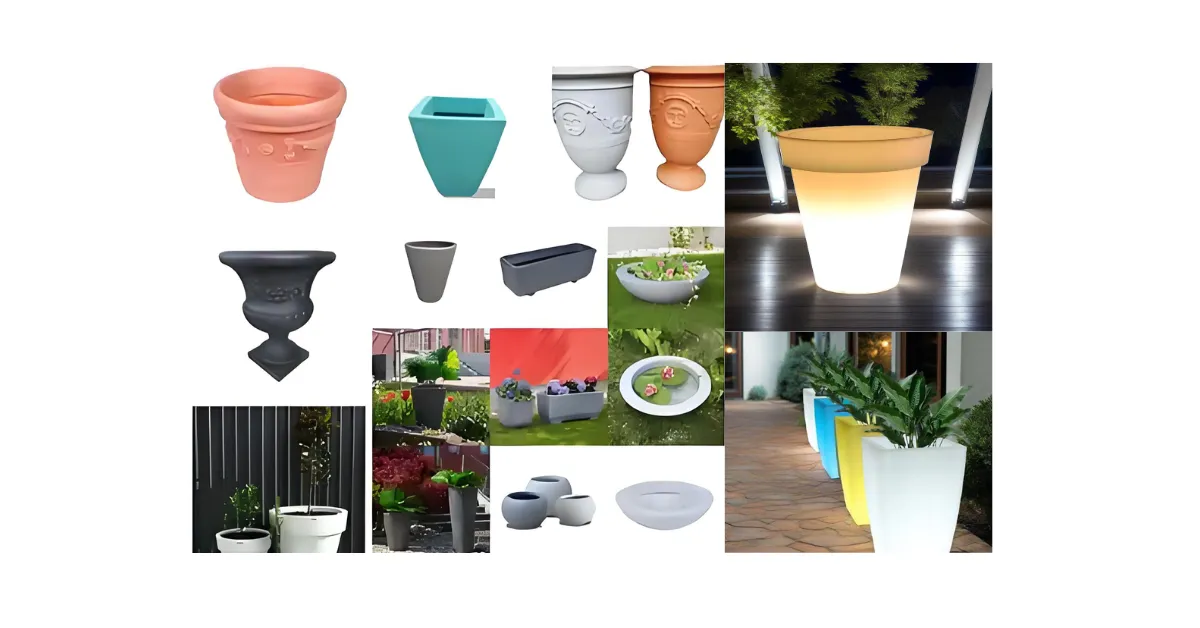

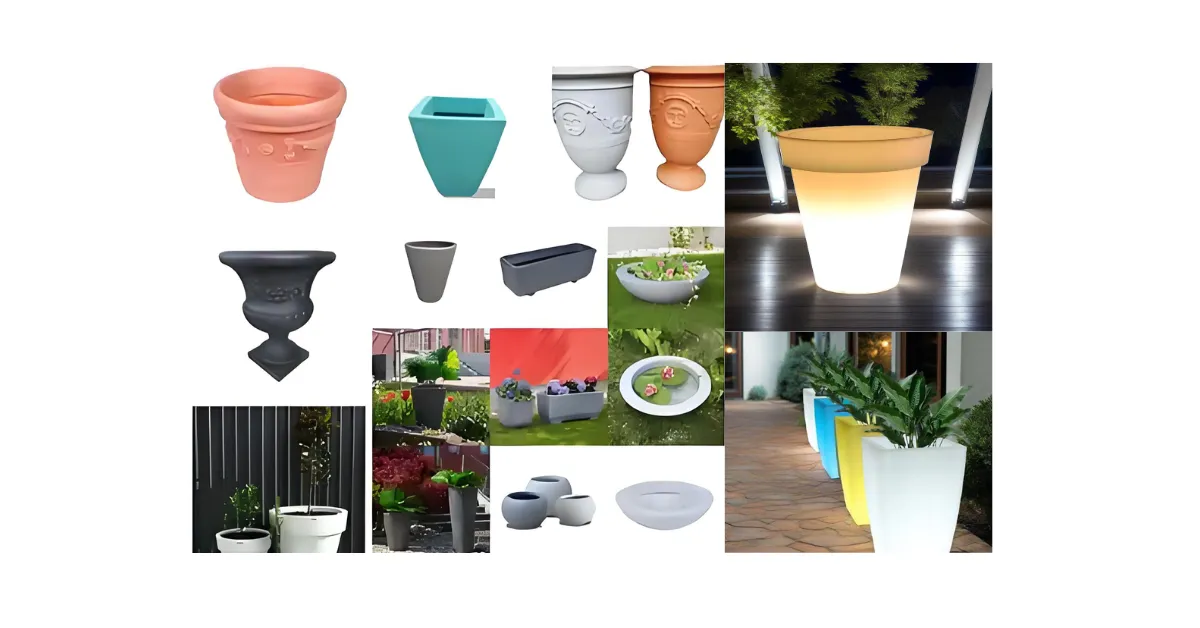

2. Design Flexibility & Customization

Rotomolded Planters:

a) Complex Shapes & Textures – Easily produces curved, textured, or double-walled designs (great for insulation).

b) Uniform Wall Thickness – No warping or sink marks, ensuring structural integrity.

b) Premium Textures – Can mimic stone, terracotta, or concrete for high-end looks.

Injection Molded Planters:

a) Limited by Mold Design – Requires simple shapes for easy demolding, often needing assembly for complex designs.

b) Smooth but Generic Finish – Requires painting or decals for decorative effects.

In this case, the rotomolded planters have more advantages in diversity and decoration. If you have many creative ideas for the shape of flower pots, please choose rotational molding planter.

3. Cost Efficiency & Production Scale

Rotomolded Planters:

a) Lower Mold Costs – Ideal for small to medium batches and custom designs.

b) Better for Large Planters – Cost-effective for oversized planters (1m+ diameter).

Injection Molded Planters:

a) High Initial Tooling Costs – Only economical for mass production of standard designs.

As we can see, the more you need large planter pot, the more you need to choose rotomolding one.

Final Verdict: Which Planter is Best?

✔ Choose Rotomolded Planters If:

-

You need long-lasting outdoor durability.

-

You want custom shapes, textures, or large sizes.

-

You prioritize eco-friendly production.

✔ Choose Injection Molded Planters If:

-

You need low-cost, mass-produced standard designs.

For high-quality, weather-resistant, and customizable planters, rotomolding is the superior choice. Explore rotomolded options for gardens, patios, and commercial landscaping today!

Keywords: Rotomolded planters, injection molded planters, best outdoor planters, durable garden pots, custom planters.

When choosing planters for gardening or home decor, the manufacturing process significantly impacts durability, aesthetics, and functionality. Rotational molding (rotomolding) and injection molding are two common plastic manufacturing techniques. So how can we make the decision between rotomold Flower Pot and the inject one? We can choose from some factors below.

1. Superior Strength & Durability

Rotomolded Planters:

a) Seamless, One-Piece Construction – No weak points or weld lines, making them highly resistant to cracks and impacts.

b) UV & Weather Resistant – Can be formulated with UV stabilizers for long-term outdoor use without fading or brittleness.

Injection Molded Planters:

a) Visible Mold Lines – Prone to stress cracks along seams over time.

b) Less Weatherproof – Often requires additional coatings for UV protection.

So if you need flower pot to decorate your beautiful outdoor garden or yard, the rotomold one will be better.

2. Design Flexibility & Customization

Rotomolded Planters:

a) Complex Shapes & Textures – Easily produces curved, textured, or double-walled designs (great for insulation).

b) Uniform Wall Thickness – No warping or sink marks, ensuring structural integrity.

b) Premium Textures – Can mimic stone, terracotta, or concrete for high-end looks.

Injection Molded Planters:

a) Limited by Mold Design – Requires simple shapes for easy demolding, often needing assembly for complex designs.

b) Smooth but Generic Finish – Requires painting or decals for decorative effects.

In this case, the rotomolded planters have more advantages in diversity and decoration. If you have many creative ideas for the shape of flower pots, please choose rotational molding planter.

3. Cost Efficiency & Production Scale

Rotomolded Planters:

a) Lower Mold Costs – Ideal for small to medium batches and custom designs.

b) Better for Large Planters – Cost-effective for oversized planters (1m+ diameter).

Injection Molded Planters:

a) High Initial Tooling Costs – Only economical for mass production of standard designs.

As we can see, the more you need large planter pot, the more you need to choose rotomolding one.

Final Verdict: Which Planter is Best?

✔ Choose Rotomolded Planters If:

-

You need long-lasting outdoor durability.

-

You want custom shapes, textures, or large sizes.

-

You prioritize eco-friendly production.

✔ Choose Injection Molded Planters If:

-

You need low-cost, mass-produced standard designs.

For high-quality, weather-resistant, and customizable planters, rotomolding is the superior choice. Explore rotomolded options for gardens, patios, and commercial landscaping today!